HDDs (introduced in 1956 as data storage for an IBM accounting computer)[5] were originally developed for use with general purpose computers. During the 1990s, the need for large-scale, reliable storage, independent of a particular device, led to the introduction of embedded systems such as RAID systems, network attached storage (NAS) systems, and storage area network (SAN) systems that provide efficient and reliable access to large volumes of data. In the 21st century, HDD usage expanded into consumer applications such as camcorders, cellphones (for example the Nokia N91), digital audio players, digital video players, digital video recorders, personal digital assistants and video game consoles.

IBM's first generation of disk drives read a track at a time, but starting with the 1301[6] IBM marketed self-formatting drives that allowed reading and writing individual records on a track. The DASD on the IBM System/360 retained this concept in the form of Count Key Data (CKD) and later Extended Count Key Data (ECKD), but from the 3375, IBM has been shipping disk drives that simulated CKD on an underlying sector-oriented disk drive. Except where stated otherwise, this article concerns itself with the sector-oriented disk drives that dominate the PC industry.

[edit] Technology

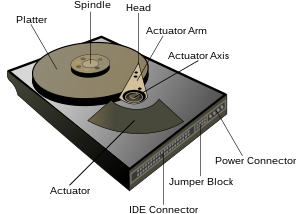

HDDs record data by magnetizing ferromagnetic material directionally, to represent either a 0 or a 1 binary digit. They read the data back by detecting the magnetization of the material. A typical HDD design consists of a spindle that holds one or more flat circular disks called platters, onto which the data is recorded. The platters are made from a non-magnetic material, usually aluminum alloy or glass, and are coated with a thin layer of magnetic material, typically 10–20 nm in thickness — for reference, standard copy paper is 0.07–0.18 millimetre (70,000–180,000 nm) thick[7] — with an outer layer of carbon for protection. Older disks used iron(III) oxide as the magnetic material, but current disks use a cobalt-based alloy.[8]

The platters are spun at very high speeds. Information is written to a platter as it rotates past devices called read-and-write heads that operate very close (tens of nanometers in new drives) over the magnetic surface. The read-and-write head is used to detect and modify the magnetization of the material immediately under it. In modern drives there is one head for each magnetic platter surface on the spindle, mounted on a common arm. An actuator arm (or access arm) moves the heads on an arc (roughly radially) across the platters as they spin, allowing each head to access almost the entire surface of the platter as it spins. The arm is moved using a voice coil actuator or in some older designs a stepper motor.

The magnetic surface of each platter is conceptually divided into many small sub-micrometre-sized magnetic regions, each of which is used to encode a single binary unit of information. Initially the regions were oriented horizontally, but beginning about 2005, the orientation was changed to perpendicular. Due to the polycrystalline nature of the magnetic material each of these magnetic regions is composed of a few hundred magnetic grains. Magnetic grains are typically 10 nm in size and each form a single magnetic domain. Each magnetic region in total forms a magnetic dipole which generates a highly localized magnetic field nearby. A write head magnetizes a region by generating a strong local magnetic field. Early HDDs used an electromagnet both to magnetize the region and to then read its magnetic field by using electromagnetic induction. Later versions of inductive heads included metal in Gap (MIG) heads and thin film heads. As data density increased, read heads using magnetoresistance (MR) came into use; the electrical resistance of the head changed according to the strength of the magnetism from the platter. Later development made use of spintronics; in these heads, the magnetoresistive effect was much greater than in earlier types, and was dubbed "giant" magnetoresistance (GMR). In today's heads, the read and write elements are separate, but in close proximity, on the head portion of an actuator arm. The read element is typically magneto-resistive while the write element is typically thin-film inductive.[9]

HD heads are kept from contacting the platter surface by the air that is extremely close to the platter; that air moves at, or close to, the platter speed.[citation needed] The record and playback head are mounted on a block called a slider, and the surface next to the platter is shaped to keep it just barely out of contact. It's a type of air bearing.

In modern drives, the small size of the magnetic regions creates the danger that their magnetic state might be lost because of thermal effects. To counter this, the platters are coated with two parallel magnetic layers, separated by a 3-atom-thick layer of the non-magnetic element ruthenium, and the two layers are magnetized in opposite orientation, thus reinforcing each other.[10] Another technology used to overcome thermal effects to allow greater recording densities is perpendicular recording, first shipped in 2005,[11] and as of 2007 the technology was used in many HDDs.[12][13][14]

| | This section may require cleanup to meet Wikipedia's quality standards. Please improve this section if you can. (December 2009) |

Grain boundaries are very important to HDD design. The grains are very small and close to each other, so the coupling between adjacent grains is very strong. When one grain is magnetized, the adjacent grains tend to be aligned parallel to it or demagnetized. Then both the stability of the data and signal-to-noise ratio will be sabotaged. A clear grain boundary can weaken the coupling of the grains and subsequently increase the signal-to-noise ratio. In longitudinal recording, the single-domain grains have uniaxial anisotropy with easy axes lying in the film plane. The consequence of this arrangement is that adjacent magnets repel each other. Therefore the magnetostatic energy is so large that it is difficult to increase areal density. Perpendicular recording media, on the other hand, has the easy axis of the grains oriented perpendicular to the disk plane. Adjacent magnets attract to each other and magnetostatic energy is much lower. So, much higher areal density can be achieved in perpendicular recording. Another unique feature in perpendicular recording is that a soft magnetic underlayer is incorporated into the recording disk. This underlayer is used to conduct writing magnetic flux so that the writing is more efficient. This will be discussed in writing process. Therefore, a higher anisotropy medium film, such as L10-FePt and rare-earth magnets, can be used.

[edit] Error handling

Modern drives also make extensive use of Error Correcting Codes (ECCs), particularly Reed–Solomon error correction. These techniques store extra bits for each block of data that are determined by mathematical formulae. The extra bits allow many errors to be fixed. While these extra bits take up space on the hard drive, they allow higher recording densities to be employed, resulting in much larger storage capacity for user data.[15] In 2009, in the newest drives, low-density parity-check codes (LDPC) are supplanting Reed-Solomon. LDPC codes enable performance close to the Shannon Limit and thus allow for the highest storage density available.[16]

Typical hard drives attempt to "remap" the data in a physical sector that is going bad to a spare physical sector—hopefully while the number of errors in that bad sector is still small enough that the ECC can completely recover the data without loss. The S.M.A.R.T. system counts the total number of errors in the entire hard drive fixed by ECC, and the total number of remappings, in an attempt to predict hard drive failure.

[edit] Architecture

A typical hard drive has two electric motors, one to spin the disks and one to position the read/write head assembly. The disk motor has an external rotor attached to the platters; the stator windings are fixed in place. The actuator has a read-write head under the tip of its very end (near center); a thin printed-circuit cable connects the read-write head to the hub of the actuator. A flexible, somewhat 'U'-shaped, ribbon cable, seen edge-on below and to the left of the actuator arm in the first image and more clearly in the second, continues the connection from the head to the controller board on the opposite side.

The head support arm is very light, but also rigid; in modern drives, acceleration at the head reaches 550 Gs.

The silver-colored structure at the upper left of the first image is the top plate of the permanent-magnet and moving coil motor that swings the heads to the desired position (it is shown removed in the second image). The plate supports a thin neodymium-iron-boron (NIB) high-flux magnet. Beneath this plate is the moving coil, often referred to as the voice coil by analogy to the coil in loudspeakers, which is attached to the actuator hub, and beneath that is a second NIB magnet, mounted on the bottom plate of the motor (some drives only have one magnet).

The voice coil itself is shaped rather like an arrowhead, and made of doubly coated copper magnet wire. The inner layer is insulation, and the outer is thermoplastic, which bonds the coil together after it's wound on a form, making it self-supporting. The portions of the coil along the two sides of the arrowhead (which point to the actuator bearing center) interact with the magnetic field, developing a tangential force that rotates the actuator. Current flowing radially outward along one side of the arrowhead and radially inward on the other produces the tangential force. If the magnetic field were uniform, each side would generate opposing forces that would cancel each other out. Therefore the surface of the magnet is half N pole, half S pole, with the radial dividing line in the middle, causing the two sides of the coil to see opposite magnetic fields and produce forces that add instead of canceling. Currents along the top and bottom of the coil produce radial forces that do not rotate the head.

[edit] Market Segmentation, Capacity and access speed

Using rigid disks and sealing the unit allows much tighter tolerances than in a floppy disk drive. Consequently, hard disk drives can store much more data than floppy disk drives and can access and transmit them faster.

- As of May 2010[update], the highest capacity consumer HDDs are 2 TB.[17]

- "Desktop HDDs" typically store between 120 GB and 2TB (although rarely above 1.5 TB of data based on US market data[18]) and rotate at 5,400 to 10,000 rpm, and have a media transfer rate of 0.5 Gbit/s or higher. (1 GB = 109 Byte; 1 Gbit/s = 109 bit/s)

- Enterprise HDDs are typically used with multiple-user computers running enterprise software. Examples are:

- transaction processing databases

- internet infrastructure (email, webserver, e-commerce)

- scientific computing software

- nearline storage management software

- The fastest enterprise HDDs spin at 10,000 or 15,000 rpm, and can achieve sequential media transfer speeds above 1.6 Gbit/s.[19] and a sustained transfer rate up to 1 Gbit/s.[19] Drives running at 10,000 or 15,000 rpm use smaller platters to mitigate increased power requirements (as they have less air drag) and therefore generally have lower capacity than the highest capacity desktop drives.

- Enterprise drives commonly operate continuously ("24/7") in demanding environments while delivering the highest possible performance without sacrificing reliability. Maximum capacity is not the primary goal, and as a result the drives are often offered in capacities that are relatively low in relation to their cost[20].

- Mobile HDDs, i.e., laptop HDDs, which are physically smaller than their desktop and enterprise counterparts, tend to be slower and have lower capacity. A typical mobile HDD spins at either 4200 rpm, 5400 rpm, or 7200 rpm, with 5400 rpm being the most prominent. 7200 rpm drives tend to be more expensive and have smaller capacities, while 4200 rpm models usually have very high storage capacities. Because of physically smaller platter(s), mobile HDDs generally have lower capacity than their larger desktop counterparts.

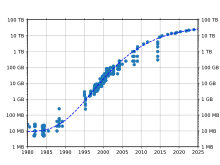

The exponential increases in disk space and data access speeds of HDDs have enabled the commercial viability of consumer products that require large storage capacities, such as digital video recorders and digital audio players.[21] In addition, the availability of vast amounts of cheap storage has made viable a variety of web-based services with extraordinary capacity requirements, such as free-of-charge web search, web archiving and video sharing (Google, Internet Archive, YouTube, etc.).

The main way to decrease access time is to increase rotational speed, thus reducing rotational delay, while the main way to increase throughput and storage capacity is to increase areal density. Based on historic trends, analysts predict a future growth in HDD bit density (and therefore capacity) of about 40% per year.[22] Access times have not kept up with throughput increases, which themselves have not kept up with growth in storage capacity.

The expected random IOPS capability of any HDD can be calculated by dividing 1000 msecs by the sum of the average seek time and the average rotational latency.

The first 3.5″ HDD marketed as able to store 1 TB was the Hitachi Deskstar 7K1000. It contains five platters at approximately 200 GB each, providing 1 TB (935.5 GB) of usable space;[23] note the difference between its capacity in decimal units (1 TB = 1012 bytes) and binary units where 1 TB = 1024 GB = 240 bytes. Hitachi has since been joined by Samsung (Samsung SpinPoint F1, which has 3 × 334 GB platters), Seagate and Western Digital in the 1 TB drive market.[24][25]

In September 2009, Showa Denko announced capacity improvements in platters that they manufacture for HDD makers. A single 2.5" platter is able to hold 334 GB worth of data, and preliminary results for 3.5" indicate a 750 GB per platter capacity.[26]

[edit] Capacity measurements

Raw unformatted capacity of a hard disk drive is usually quoted with SI prefixes (metric system prefixes), incrementing by powers of 1000; today that usually means gigabytes (GB) and terabytes (TB). This is conventional for data speeds and memory sizes which are not inherently manufactured in power of two sizes, as RAM and Flash memory are. Hard disks by contrast have no inherent binary size as capacity is determined by number of heads, tracks and sectors.

This can cause some confusion because some operating systems may report the formatted capacity of a hard drive using binary prefix units which increment by powers of 1024.

A one terabyte (1 TB) disk drive would be expected to hold around 1 trillion bytes (1,000,000,000,000) or 1000 GB; and indeed most 1 TB hard drives will contain slightly more than this number. However some operating system utilities would report this as around 931 GB or 953,674 MB. (The actual number for a formatted capacity will be somewhat smaller still, depending on the file system). Following are the several ways of reporting one Terabyte.

| SI prefixes (hard drive) | equivalent | Binary prefixes (OS) | equivalent |

|---|---|---|---|

| 1 TB (Terabyte) | 1 * 10004 B | 0.9095 TB (Terabyte) | 0.9095 * 10244 B |

| 1000 GB (Gigabyte) | 1000 * 10003 B | 931.3 GB (Gigabyte) | 931.3 * 10243 B |

| 1,000,000 MB (Megabyte) | 1,000,000 * 10002 B | 953,674.3 MB (Megabyte) | 953,674.3 * 10242 B |

| 1,000,000,000 KB (Kilobyte) | 1,000,000,000 * 1000 B | 976,562,500 KB (Kilobyte) | 976,562,500 * 1024 B |

| 1,000,000,000,000 B (byte) | - | 1,000,000,000,000 B (byte) | - |

Microsoft Windows reports disk capacity both in a decimal integer to 12 or more digits and in binary prefix units to three significant digits.

The capacity of an HDD can be calculated by multiplying the number of cylinders by the number of heads by the number of sectors by the number of bytes/sector (most commonly 512). Drives with the ATA interface and a capacity of eight gigabytes or more behave as if they were structured into 16383 cylinders, 16 heads, and 63 sectors, for compatibility with older operating systems. Unlike in the 1980s, the cylinder, head, sector (C/H/S) counts reported to the CPU by a modern ATA drive are no longer actual physical parameters since the reported numbers are constrained by historic operating-system interfaces and with zone bit recording the actual number of sectors varies by zone. Disks with SCSI interface address each sector with a unique integer number; the operating system remains ignorant of their head or cylinder count.

The old C/H/S scheme has been replaced by logical block addressing. In some cases, to try to "force-fit" the C/H/S scheme to large-capacity drives, the number of heads was given as 64, although no modern drive has anywhere near 32 platters.

For a formatted drive, the operating system's file system internal usage is another, although minor, reason why a computer hard drive or storage device's capacity may show its capacity as different from its theoretical capacity. This would include storage for, as examples, a file allocation table (FAT) or inodes, as well as other operating system data structures. This file system overhead is usually less than 1% on drives larger than 100 MB. For RAID drives, data integrity and fault-tolerance requirements also reduce the realized capacity. For example, a RAID1 drive will be about half the total capacity as a result of data mirroring. For RAID5 drives with x drives you would lose 1/x of your space to parity. RAID drives are multiple drives that appear to be one drive to the user, but provides some fault-tolerance.

A general rule of thumb to quickly convert the manufacturer's hard disk capacity to the standard Microsoft Windows formatted capacity is 0.93*capacity of HDD from manufacturer for HDDs less than a terabyte and 0.91*capacity of HDD from manufacturer for HDDs equal to or greater than 1 terabyte.

[edit] Form factors

Before the era of PCs and small computers, hard disks were of widely varying dimensions, typically in free standing cabinets the size of washing machines (e.g. DEC RP06 Disk Drive) or designed so that dimensions enabled placement in a 19" rack (e.g. Diablo Model 31).

With increasing sales of small computers having built in floppy-disk drives (FDDs), HDDs that would fit to the FDD mountings became desirable, and this led to the evolution of the market towards drives with certain Form factors, initially derived from the sizes of 8", 5.25" and 3.5" floppy disk drives. Smaller sizes than 3.5" have emerged as popular in the marketplace and/or been decided by various industry groups.

- 8 in: 9.5 in × 4.624 in × 14.25 in (241.3 mm × 117.5 mm × 362 mm)

In 1979, Shugart Associates' SA1000 was the first form factor compatible HDD, having the same dimensions and a compatible interface to the 8″ FDD. - 5.25 inch: 5.75 in × 1.63 in × 8 in (146.1 mm × 41.4 mm × 203 mm)

This smaller form factor, first used in an HDD by Seagate in 1980,[27] was the same size as full height 5¼-inch diameter FDD, i.e., 3.25 inches high. This is twice as high as "half height" commonly used today; i.e., 1.63 in (41.4 mm). Most desktop models of drives for optical 120 mm disks (DVD, CD) use the half height 5¼″ dimension, but it fell out of fashion for HDDs. The Quantum Bigfoot HDD was the last to use it in the late 1990s, with “low-profile” (≈25 mm) and “ultra-low-profile” (≈20 mm) high versions. - 3.5 inch: 4 in × 1 in × 5.75 in (101.6 mm × 25.4 mm × 146 mm) = 376.77344 cm³

This smaller form factor, first used in an HDD by Rodime in 1983,[28] was the same size as the "half height" 3½″ FDD, i.e., 1.63 inches high. Today it has been largely superseded by 1-inch high “slimline” or “low-profile” versions of this form factor which is used by most desktop HDDs. - 2.5 inch: 2.75 in × 0.374–0.59 in × 3.945 in (69.85 mm × 7–15 mm × 100 mm) = 48.895–104.775 cm3

This smaller form factor was introduced by PrairieTek in 1988;[29] there is no corresponding FDD. It is widely used today for hard-disk drives in mobile devices (laptops, music players, etc.) and as of 2008 replacing 3.5 inch enterprise-class drives.[30] It is also used in the Xbox 360 and Playstation 3 video game consoles.[citation needed] Today, the dominant height of this form factor is 9.5 mm for laptop drives (usually having two platters inside), but higher capacity drives have a height of 12.5 mm (usually having three platters). Enterprise-class drives can have a height up to 15 mm.[31] Seagate has released a wafer-thin 7mm drive aimed at entry level laptops and high end netbooks in December 2009.[32] - 1.8 inch: 54 mm × 8 mm × 71 mm = 30.672 cm³

This form factor, originally introduced by Integral Peripherals in 1993, has evolved into the ATA-7 LIF with dimensions as stated. It is increasingly used in digital audio players and subnotebooks. An original variant exists for 2–5 GB sized HDDs that fit directly into a PC card expansion slot. These became popular for their use in iPods and other HDD based MP3 players. - 1 inch: 42.8 mm × 5 mm × 36.4 mm

This form factor was introduced in 1999 as IBM's Microdrive to fit inside a CF Type II slot. Samsung calls the same form factor "1.3 inch" drive in its product literature.[33] - 0.85 inch: 24 mm × 5 mm × 32 mm

Toshiba announced this form factor in January 2004[34] for use in mobile phones and similar applications, including SD/MMC slot compatible HDDs optimized for video storage on 4G handsets. Toshiba currently sells a 4 GB (MK4001MTD) and 8 GB (MK8003MTD) version [2] and holds the Guinness World Record for the smallest hard disk drive.[35]

3.5" and 2.5" hard disks currently dominate the market.

By 2009 all manufacturers had discontinued the development of new products for the 1.3-inch, 1-inch and 0.85-inch form factors due to falling prices of flash memory.[36][37]

The inch-based nickname of all these form factors usually do not indicate any actual product dimension (which are specified in millimeters for more recent form factors), but just roughly indicate a size relative to disk diameters, in the interest of historic continuity.

[edit] Current hard disk form factors

| Form factor | Width | Height | Largest capacity | Platters (Max) |

|---|---|---|---|---|

| 3.5″ | 102 mm | 25.4 mm | 2 TB[38] (2009) | 5 |

| 2.5″ | 69.9 mm | 7–15 mm | 1 TB[39] (2009) | 3 |

| 1.8″ | 54 mm | 8 mm | 320 GB[40] (2009) | 3 |

[edit] Obsolete hard disk form factors

| Form factor | Width | Largest capacity | Platters (Max) |

|---|---|---|---|

| 5.25″ FH | 146 mm | 47 GB[41] (1998) | 14 |

| 5.25″ HH | 146 mm | 19.3 GB[42] (1998) | 4[43] |

| 1.3″ | 43 mm | 40 GB[44] (2007) | 1 |

| 1″ (CFII/ZIF/IDE-Flex) | 42 mm | 20 GB (2006) | 1 |

| 0.85″ | 24 mm | 8 GB[45] (2004) | 1 |

[edit] Performance characteristics

[edit] Data transfer rate

As of 2008, a typical 7200 rpm desktop hard drive has a sustained "disk-to-buffer" data transfer rate of about 70 megabytes per second.[46] This rate depends on the track location, so it will be higher for data on the outer tracks (where there are more data sectors) and lower toward the inner tracks (where there are fewer data sectors); and is generally somewhat higher for 10,000 rpm drives. A current widely used standard for the "buffer-to-computer" interface is 3.0 Gbit/s SATA, which can send about 300 megabyte/s from the buffer to the computer, and thus is still comfortably ahead of today's disk-to-buffer transfer rates. Data transfer rate (read/write) can be measured by writing a large file to disk using special file generator tools, then reading back the file. Transfer rate can be influenced by file system fragmentation and the layout of the files.

The mechanical nature of hard disks introduces certain performance compromises. The manipulation of sequential data depends upon the rotational speed of the platters and the data recording density. Because heat and vibration limit rotational speed, advancing density becomes the sole method to improve sequential transfer rates. While these advances exponentially increase storage capacity, the performance gains they enable are linear. Throughput relative to capacity in new generations of hard disks has therefore fallen with time.

[edit] Seek time

Seek time for non-sequential data ranges from 3 ms[47] for high-end server drives, to 15 ms for mobile drives, with the most common mobile drives at about 12 ms[48] and the most common desktop type typically being around 9 ms There has not been any significant improvement in this speed for some years. Some early PC drives used a stepper motor to move the heads, and as a result had access times as slow as 80–120 ms, but this was quickly improved by voice coil type actuation in the late 1980s, reducing access times to around 20 ms.

[edit] Power consumption

Power consumption has become increasingly important, not just in mobile devices such as laptops but also in server and desktop markets. Increasing data center machine density has led to problems delivering sufficient power to devices (especially for spin up), and getting rid of the waste heat subsequently produced, as well as environmental and electrical cost concerns (see green computing). Similar issues exist for large companies with thousands of desktop PCs. Smaller form factor drives often use less power than larger drives. One interesting development in this area is actively controlling the seek speed so that the head arrives at its destination only just in time to read the sector, rather than arriving as quickly as possible and then having to wait for the sector to come around (i.e. the rotational latency). Many of the hard drive companies are now producing Green Drives that require much less power and cooling. Many of these 'Green Drives' spin slower (<5,400>

Also in Server and Workstation systems where there might be multiple hard disk drives, there are various ways of controlling when the hard drives spin up (highest power draw).

On SCSI hard disk drives, the SCSI controller can directly control spin up and spin down of the drives.

On Parallel ATA (aka PATA) and SATA hard disk drives, some support Power-up in standby or PUIS. The hard disk drive will not spin up until the controller or system BIOS issues a specific command to do so. This limits the power draw or consumption upon power on.

On newer SATA hard disk drives, there is Staggered Spin Up feature. The hard disk drive will not spin up until the SATA Phy comes ready (communications with the host controller starts).[citation needed]

To further control or reduce power draw and consumption, the hard disk drive can be spun down to reduce its power consumption.

[edit] Audible noise

Measured in dBA, audible noise is significant for certain applications, such as PVRs, digital audio recording and quiet computers. Low noise disks typically use fluid bearings, slower rotational speeds (usually 5,400 rpm) and reduce the seek speed under load (AAM) to reduce audible clicks and crunching sounds. Drives in smaller form factors (e.g. 2.5 inch) are often quieter than larger drives.

[edit] Shock resistance

Shock resistance is especially important for mobile devices. Some laptops now include active hard drive protection that parks the disk heads if the machine is dropped, hopefully before impact, to offer the greatest possible chance of survival in such an event. Maximum shock tolerance to date is 350 Gs for operating and 1000 Gs for non-operating.[49]

[edit] Access and interfaces

| This section needs additional citations for verification.

Please help improve this article by adding reliable references. Unsourced material may be challenged and removed. (July 2009) |

Hard disk drives are accessed over one of a number of bus types, including parallel ATA (P-ATA, also called IDE or EIDE), Serial ATA (SATA), SCSI, Serial Attached SCSI (SAS), and Fibre Channel. Bridge circuitry is sometimes used to connect hard disk drives to buses that they cannot communicate with natively, such as IEEE 1394, USB and SCSI.

For the ST-506 interface, the data encoding scheme as written to the disk surface was also important. The first ST-506 disks used Modified Frequency Modulation (MFM) encoding, and transferred data at a rate of 5 megabits per second. Later controllers using 2,7 RLL (or just "RLL") encoding caused 50% more data to appear under the heads compared to one rotation of an MFM drive, increasing data storage and data transfer rate by 50%, to 7.5 megabits per second.

Many ST-506 interface disk drives were only specified by the manufacturer to run at the 1/3rd lower MFM data transfer rate compared to RLL, while other drive models (usually more expensive versions of the same drive) were specified to run at the higher RLL data transfer rate. In some cases, a drive had sufficient margin to allow the MFM specified model to run at the denser/faster RLL data transfer rate (not recommended nor guaranteed by manufacturers). Also, any RLL-certified drive could run on any MFM controller, but with 1/3 less data capacity and as much as 1/3rd less data transfer rate compared to its RLL specifications.

Enhanced Small Disk Interface (ESDI) also supported multiple data rates (ESDI disks always used 2,7 RLL, but at 10, 15 or 20 megabits per second), but this was usually negotiated automatically by the disk drive and controller; most of the time, however, 15 or 20 megabit ESDI disk drives weren't downward compatible (i.e. a 15 or 20 megabit disk drive wouldn't run on a 10 megabit controller). ESDI disk drives typically also had jumpers to set the number of sectors per track and (in some cases) sector size.

Modern hard drives present a consistent interface to the rest of the computer, no matter what data encoding scheme is used internally. Typically a DSP in the electronics inside the hard drive takes the raw analog voltages from the read head and uses PRML and Reed–Solomon error correction[50] to decode the sector boundaries and sector data, then sends that data out the standard interface. That DSP also watches the error rate detected by error detection and correction, and performs bad sector remapping, data collection for Self-Monitoring, Analysis, and Reporting Technology, and other internal tasks.

SCSI originally had just one signaling frequency of 5 MHz for a maximum data rate of 5 megabytes/second over 8 parallel conductors, but later this was increased dramatically. The SCSI bus speed had no bearing on the disk's internal speed because of buffering between the SCSI bus and the disk drive's internal data bus; however, many early disk drives had very small buffers, and thus had to be reformatted to a different interleave (just like ST-506 disks) when used on slow computers, such as early Commodore Amiga, IBM PC compatibles and Apple Macintoshes.

ATA disks have typically had no problems with interleave or data rate, due to their controller design, but many early models were incompatible with each other and couldn't run with two devices on the same physical cable in a master/slave setup. This was mostly remedied by the mid-1990s, when ATA's specification was standardized and the details began to be cleaned up, but still causes problems occasionally (especially with CD-ROM and DVD-ROM disks, and when mixing Ultra DMA and non-UDMA devices).

Serial ATA does away with master/slave setups entirely, placing each disk on its own channel (with its own set of I/O ports) instead.

FireWire/IEEE 1394 and USB(1.0/2.0) HDDs are external units containing generally ATA or SCSI disks with ports on the back allowing very simple and effective expansion and mobility. Most FireWire/IEEE 1394 models are able to daisy-chain in order to continue adding peripherals without requiring additional ports on the computer itself. USB however, is a point to point network and doesn't allow for daisy-chaining. USB hubs are used to increase the number of available ports and are used for devices that don't require charging since the current supplied by hubs is typically lower than what's available from the built-in USB ports.

[edit] Disk interface families used in personal computers

Notable families of disk interfaces include:

- Historical bit serial interfaces — connect a hard disk drive (HDD) to a hard disk controller (HDC) with two cables, one for control and one for data. (Each drive also has an additional cable for power, usually connecting it directly to the power supply unit). The HDC provided significant functions such as serial/parallel conversion, data separation, and track formatting, and required matching to the drive (after formatting) in order to assure reliability. Each control cable could serve two or more drives, while a dedicated (and smaller) data cable served each drive.

- ST506 used MFM (Modified Frequency Modulation) for the data encoding method.

- ST412 was available in either MFM or RLL (Run Length Limited) encoding variants.

- Enhanced Small Disk Interface (ESDI) was an interface developed by Maxtor to allow faster communication between the processor and the disk than MFM or RLL.

- Modern bit serial interfaces — connect a hard disk drive to a host bus interface adapter (today typically integrated into the "south bridge") with one data/control cable. (As for historical bit serial interfaces above, each drive also has an additional power cable, usually direct to the power supply unit.)

- Fibre Channel (FC), is a successor to parallel SCSI interface on enterprise market. It is a serial protocol. In disk drives usually the Fibre Channel Arbitrated Loop (FC-AL) connection topology is used. FC has much broader usage than mere disk interfaces, and it is the cornerstone of storage area networks (SANs). Recently other protocols for this field, like iSCSI and ATA over Ethernet have been developed as well. Confusingly, drives usually use copper twisted-pair cables for Fibre Channel, not fibre optics. The latter are traditionally reserved for larger devices, such as servers or disk array controllers.

- Serial ATA (SATA). The SATA data cable has one data pair for differential transmission of data to the device, and one pair for differential receiving from the device, just like EIA-422. That requires that data be transmitted serially. Similar differential signaling system is used in RS485, LocalTalk, USB, Firewire, and differential SCSI.

- Serial Attached SCSI (SAS). The SAS is a new generation serial communication protocol for devices designed to allow for much higher speed data transfers and is compatible with SATA. SAS uses a mechanically identical data and power connector to standard 3.5" SATA1/SATA2 HDDs, and many server-oriented SAS RAID controllers are also capable of addressing SATA hard drives. SAS uses serial communication instead of the parallel method found in traditional SCSI devices but still uses SCSI commands.

- Word serial interfaces — connect a hard disk drive to a host bus adapter (today typically integrated into the "south bridge") with one cable for combined data/control. (As for all bit serial interfaces above, each drive also has an additional power cable, usually direct to the power supply unit.) The earliest versions of these interfaces typically had a 8 bit parallel data transfer to/from the drive, but 16 bit versions became much more common, and there are 32 bit versions. Modern variants have serial data transfer. The word nature of data transfer makes the design of a host bus adapter significantly simpler than that of the precursor HDD controller.

- Integrated Drive Electronics (IDE), later renamed to ATA, with the alias P-ATA ("parallel ATA") retroactively added upon introduction of the new variant Serial ATA. The original name reflected the innovative integration of HDD controller with HDD itself, which was not found in earlier disks. Moving the HDD controller from the interface card to the disk drive helped to standardize interfaces, and to reduce the cost and complexity. The 40 pin IDE/ATA connection transfers 16 bits of data at a time on the data cable. The data cable was originally 40 conductor, but later higher speed requirements for data transfer to and from the hard drive led to an "ultra DMA" mode, known as UDMA. Progressively faster versions of this standard ultimately added the requirement for an 80 conductor variant of the same cable; where half of the conductors provides grounding necessary for enhanced high-speed signal quality by reducing cross talk. The interface for 80 conductor only has 39 pins, the missing pin acting as a key to prevent incorrect insertion of the connector to an incompatible socket, a common cause of disk and controller damage.

- EIDE was an unofficial update (by Western Digital) to the original IDE standard, with the key improvement being the use of direct memory access (DMA) to transfer data between the disk and the computer without the involvement of the CPU, an improvement later adopted by the official ATA standards. By directly transferring data between memory and disk, DMA eliminates the need for the CPU to copy byte per byte, therefore allowing it to process other tasks while the data transfer occurs.

- Small Computer System Interface (SCSI), originally named SASI for Shugart Associates System Interface, was an early competitor of ESDI. SCSI disks were standard on servers, workstations, Commodore Amiga and Apple Macintosh computers through the mid-90s, by which time most models had been transitioned to IDE (and later, SATA) family disks. Only in 2005 did the capacity of SCSI disks fall behind IDE disk technology, though the highest-performance disks are still available in SCSI and Fibre Channel only. The length limitations of the data cable allows for external SCSI devices. Originally SCSI data cables used single ended (common mode) data transmission, but server class SCSI could use differential transmission, either low voltage differential (LVD) or high voltage differential (HVD). ("Low" and "High" voltages for differential SCSI are relative to SCSI standards and do not meet the meaning of low voltage and high voltage as used in general electrical engineering contexts, as apply e.g. to statutory electrical codes; both LVD and HVD use low voltage signals (3.3 V and 5 V respectively) in general terminology.)

| Acronym or abbreviation | Meaning | Description |

|---|---|---|

| SASI | Shugart Associates System Interface | Historical predecessor to SCSI. |

| SCSI | Small Computer System Interface | Bus oriented that handles concurrent operations. |

| SAS | Serial Attached SCSI | Improvement of SCSI, uses serial communication instead of parallel. |

| ST-506 | Seagate Technology | Historical Seagate interface. |

| ST-412 | Seagate Technology | Historical Seagate interface (minor improvement over ST-506). |

| ESDI | Enhanced Small Disk Interface | Historical; backwards compatible with ST-412/506, but faster and more integrated. |

| ATA (PATA) | Advanced Technology Attachment | Successor to ST-412/506/ESDI by integrating the disk controller completely onto the device. Incapable of concurrent operations. |

| SATA | Serial ATA | Modification of ATA, uses serial communication instead of parallel. |

[edit] Integrity

Due to the extremely close spacing between the heads and the disk surface, any contamination of the read-write heads or platters can lead to a head crash — a failure of the disk in which the head scrapes across the platter surface, often grinding away the thin magnetic film and causing data loss. Head crashes can be caused by electronic failure, a sudden power failure, physical shock, wear and tear, corrosion, or poorly manufactured platters and heads.

The HDD's spindle system relies on air pressure inside the disk enclosure to support the heads at their proper flying height while the disk rotates. Hard disk drives require a certain range of air pressures in order to operate properly. The connection to the external environment and pressure occurs through a small hole in the enclosure (about 0.5 mm in diameter), usually with a filter on the inside (the breather filter).[51] If the air pressure is too low, then there is not enough lift for the flying head, so the head gets too close to the disk, and there is a risk of head crashes and data loss. Specially manufactured sealed and pressurized disks are needed for reliable high-altitude operation, above about 3,000 m (10,000 feet).[52] Modern disks include temperature sensors and adjust their operation to the operating environment. Breather holes can be seen on all disk drives — they usually have a sticker next to them, warning the user not to cover the holes. The air inside the operating drive is constantly moving too, being swept in motion by friction with the spinning platters. This air passes through an internal recirculation (or "recirc") filter to remove any leftover contaminants from manufacture, any particles or chemicals that may have somehow entered the enclosure, and any particles or outgassing generated internally in normal operation. Very high humidity for extended periods can corrode the heads and platters.

For giant magnetoresistive (GMR) heads in particular, a minor head crash from contamination (that does not remove the magnetic surface of the disk) still results in the head temporarily overheating, due to friction with the disk surface, and can render the data unreadable for a short period until the head temperature stabilizes (so called "thermal asperity", a problem which can partially be dealt with by proper electronic filtering of the read signal).

[edit] Actuation of moving arm

The hard drive's electronics control the movement of the actuator and the rotation of the disk, and perform reads and writes on demand from the disk controller. Feedback of the drive electronics is accomplished by means of special segments of the disk dedicated to servo feedback. These are either complete concentric circles (in the case of dedicated servo technology), or segments interspersed with real data (in the case of embedded servo technology). The servo feedback optimizes the signal to noise ratio of the GMR sensors by adjusting the voice-coil of the actuated arm. The spinning of the disk also uses a servo motor. Modern disk firmware is capable of scheduling reads and writes efficiently on the platter surfaces and remapping sectors of the media which have failed.

[edit] Landing zones and load/unload technology

Modern HDDs prevent power interruptions or other malfunctions from landing its heads in the data zone by parking the heads either in a landing zone or by unloading (i.e., load/unload) the heads. Some early PC HDDs did not park the heads automatically and they would land on data. In some other early units the user manually parked the heads by running a program to park the HDD's heads.

A landing zone is an area of the platter usually near its inner diameter (ID), where no data is stored. This area is called the Contact Start/Stop (CSS) zone. Disks are designed such that either a spring or, more recently, rotational inertia in the platters is used to park the heads in the case of unexpected power loss. In this case, the spindle motor temporarily acts as a generator, providing power to the actuator.

Spring tension from the head mounting constantly pushes the heads towards the platter. While the disk is spinning, the heads are supported by an air bearing and experience no physical contact or wear. In CSS drives the sliders carrying the head sensors (often also just called heads) are designed to survive a number of landings and takeoffs from the media surface, though wear and tear on these microscopic components eventually takes its toll. Most manufacturers design the sliders to survive 50,000 contact cycles before the chance of damage on startup rises above 50%. However, the decay rate is not linear: when a disk is younger and has had fewer start-stop cycles, it has a better chance of surviving the next startup than an older, higher-mileage disk (as the head literally drags along the disk's surface until the air bearing is established). For example, the Seagate Barracuda 7200.10 series of desktop hard disks are rated to 50,000 start-stop cycles, in other words no failures attributed to the head-platter interface were seen before at least 50,000 start-stop cycles during testing.[53]

Around 1995 IBM pioneered a technology where a landing zone on the disk is made by a precision laser process (Laser Zone Texture = LZT) producing an array of smooth nanometer-scale "bumps" in a landing zone,[54] thus vastly improving stiction and wear performance. This technology is still largely in use today (2008), predominantly in desktop and enterprise (3.5 inch) drives. In general, CSS technology can be prone to increased stiction (the tendency for the heads to stick to the platter surface), e.g. as a consequence of increased humidity. Excessive stiction can cause physical damage to the platter and slider or spindle motor.

Load/Unload technology relies on the heads being lifted off the platters into a safe location, thus eliminating the risks of wear and stiction altogether. The first HDD RAMAC and most early disk drives used complex mechanisms to load and unload the heads. Modern HDDs use ramp loading, first introduced by Memorex in 1967,[55] to load/unload onto plastic "ramps" near the outer disk edge.

All HDDs today still use one of these two technologies listed above. Each has a list of advantages and drawbacks in terms of loss of storage area on the disk, relative difficulty of mechanical tolerance control, non-operating shock robustness, cost of implementation, etc.

Addressing shock robustness, IBM also created a technology for their ThinkPad line of laptop computers called the Active Protection System. When a sudden, sharp movement is detected by the built-in accelerometer in the Thinkpad, internal hard disk heads automatically unload themselves to reduce the risk of any potential data loss or scratch defects. Apple later also utilized this technology in their PowerBook, iBook, MacBook Pro, and MacBook line, known as the Sudden Motion Sensor. Sony,[56] HP with their HP 3D DriveGuard[57] and Toshiba[58] have released similar technology in their notebook computers.

This accelerometer based shock sensor has also been used for building cheap earthquake sensor networks.[59]

[edit] Disk failures and their metrics

| Wikibooks has a book on the topic of |

Most major hard disk and motherboard vendors now support S.M.A.R.T. (Self-Monitoring, Analysis, and Reporting Technology), which measures drive characteristics such as operating temperature, spin-up time, data error rates, etc. Certain trends and sudden changes in these parameters are thought to be associated with increased likelihood of drive failure and data loss.

However, not all failures are predictable. Normal use eventually can lead to a breakdown in the inherently fragile device, which makes it essential for the user to periodically back up the data onto a separate storage device. Failure to do so can lead to the loss of data. While it may sometimes be possible to recover lost information, it is normally an extremely costly procedure, and it is not possible to guarantee success. A 2007 study published by Google suggested very little correlation between failure rates and either high temperature or activity level; however, the correlation between manufacturer/model and failure rate was relatively strong. Statistics in this matter is kept highly secret by most entities. Google did not publish the manufacturer's names along with their respective failure rates,[60] though they have since revealed that they use Hitachi Deskstar drives in some of their servers.[61] While several S.M.A.R.T. parameters have an impact on failure probability, a large fraction of failed drives do not produce predictive S.M.A.R.T. parameters.[60] S.M.A.R.T. parameters alone may not be useful for predicting individual drive failures.[60]

A common misconception is that a colder hard drive will last longer than a hotter hard drive. The Google study seems to imply the reverse—"lower temperatures are associated with higher failure rates". Hard drives with S.M.A.R.T.-reported average temperatures below 27 °C (80.6 °F) had higher failure rates than hard drives with the highest reported average temperature of 50 °C (122 °F), failure rates at least twice as high as the optimum S.M.A.R.T.-reported temperature range of 36 °C (96.8 °F) to 47 °C (116.6 °F).[60]

SCSI, SAS and FC drives are typically more expensive and are traditionally used in servers and disk arrays, whereas inexpensive ATA and SATA drives evolved in the home computer market and were perceived to be less reliable. This distinction is now becoming blurred.

The mean time between failures (MTBF) of SATA drives is usually about 600,000 hours (some drives such as Western Digital Raptor have rated 1.4 million hours MTBF)[62], while SCSI drives are rated for upwards of 1.5 million hours.[citation needed] However, independent research indicates that MTBF is not a reliable estimate of a drive's longevity.[63] MTBF is conducted in laboratory environments in test chambers and is an important metric to determine the quality of a disk drive before it enters high volume production. Once the drive product is in production, the more valid metric is annualized failure rate (AFR).[citation needed] AFR is the percentage of real-world drive failures after shipping.

SAS drives are comparable to SCSI drives, with high MTBF and high reliability.[citation needed]

Enterprise S-ATA drives designed and produced for enterprise markets, unlike standard S-ATA drives, have reliability comparable to other enterprise class drives.[64][65]

Typically enterprise drives (all enterprise drives, including SCSI, SAS, enterprise SATA and FC) experience between 0.70%-0.78% annual failure rates from the total installed drives. [citation needed]

Eventually all mechanical hard disk drives fail, so to mitigate loss of data, some form of redundancy is needed, such as RAID[66] or a regular backup[66] system.

[edit] Manufacturers

The technological resources and know-how required for modern drive development and production mean that as of 2010, virtually all of the world's HDDs are manufactured by just five large companies: Seagate, Western Digital, Hitachi, Samsung, and Toshiba.

Dozens of former HDD manufacturers have gone out of business, merged, or closed their HDD divisions; as capacities and demand for products increased, profits became hard to find, and the market underwent significant consolidation in the late 1980s and late 1990s. The first notable casualty of the business in the PC era was Computer Memories Inc. or CMI; after an incident with faulty 20 MB AT disks in 1985,[67] CMI's reputation never recovered, and they exited the HDD business in 1987. Another notable failure was MiniScribe, who went bankrupt in 1990 after it was found that they had engaged in accounting fraud and inflated sales numbers for several years. Many other smaller companies (like Kalok, Microscience, LaPine, Areal, Priam and PrairieTek) also did not survive the shakeout, and had disappeared by 1993; Micropolis was able to hold on until 1997, and JTS, a relative latecomer to the scene, lasted only a few years and was gone by 1999, after attempting to manufacture HDDs in India. Their claim to fame was creating a new 3″ form factor drive for use in laptops. Quantum and Integral also invested in the 3″ form factor; but eventually ceased support as this form factor failed to catch on. Rodime was also an important manufacturer during the 1980s, but stopped making disks in the early 1990s amid the shakeout and now concentrates on technology licensing; they hold a number of patents related to 3.5-inch form factor HDDs.

The following is the genealogy of the current HDD companies:

- 1967: Hitachi enters the HDD business.

- 1967: Toshiba enters the HDD business.

- 1979: Seagate Technology[68] founded.

- 1988: Western Digital, then a well-known controller designer, enters the HDD business by acquiring Tandon Corporation's disk manufacturing division.[69]

- 1989: Seagate Technology purchases Control Data's HDD business.

- 1990: Maxtor purchases MiniScribe out of bankruptcy, making it the core of its low-end HDDs.

- 1994: Quantum purchases DEC's storage division, giving it a high-end disk range to go with its more consumer-oriented ProDrive range.

- 1996: Seagate acquires Conner Peripherals in a merger.

- 2000: Maxtor acquires Quantum's HDD business; Quantum remains in the tape business.

- 2003: Hitachi acquires the majority of IBM's disk division, renaming it Hitachi Global Storage Technologies (HGST).

- 2006: Seagate acquires Maxtor.

- 2009: Toshiba acquires Fujitsu's HDD division.[70]

This was so awesome.At least now i know something about hard drives.I was so green about everything and even always had it in mind that my hard drive can crash anytime.This made me even prepare by making backups and this is online with www.safecopybackup.com but am now so glad that the above information has taught me alot about hard drives and how to keep my hard drive from getting damaged.Thanks once again

ReplyDelete